A client called to report that most of his lights had turned off. I assessed the situation and discovered that the lights had just been turned off.. I was surprised, as this was my first meeting with such an issue in my 10 years of experience.

Two days after servicing the lights, I received another call from the client. They stated that one of the replaced lights had gone out. Since it had rained that day, I returned to inspect the issue. Upon checking, I discovered that water was leaking from the PVC pipe. This leakage explained why some of the lights had stopped working.

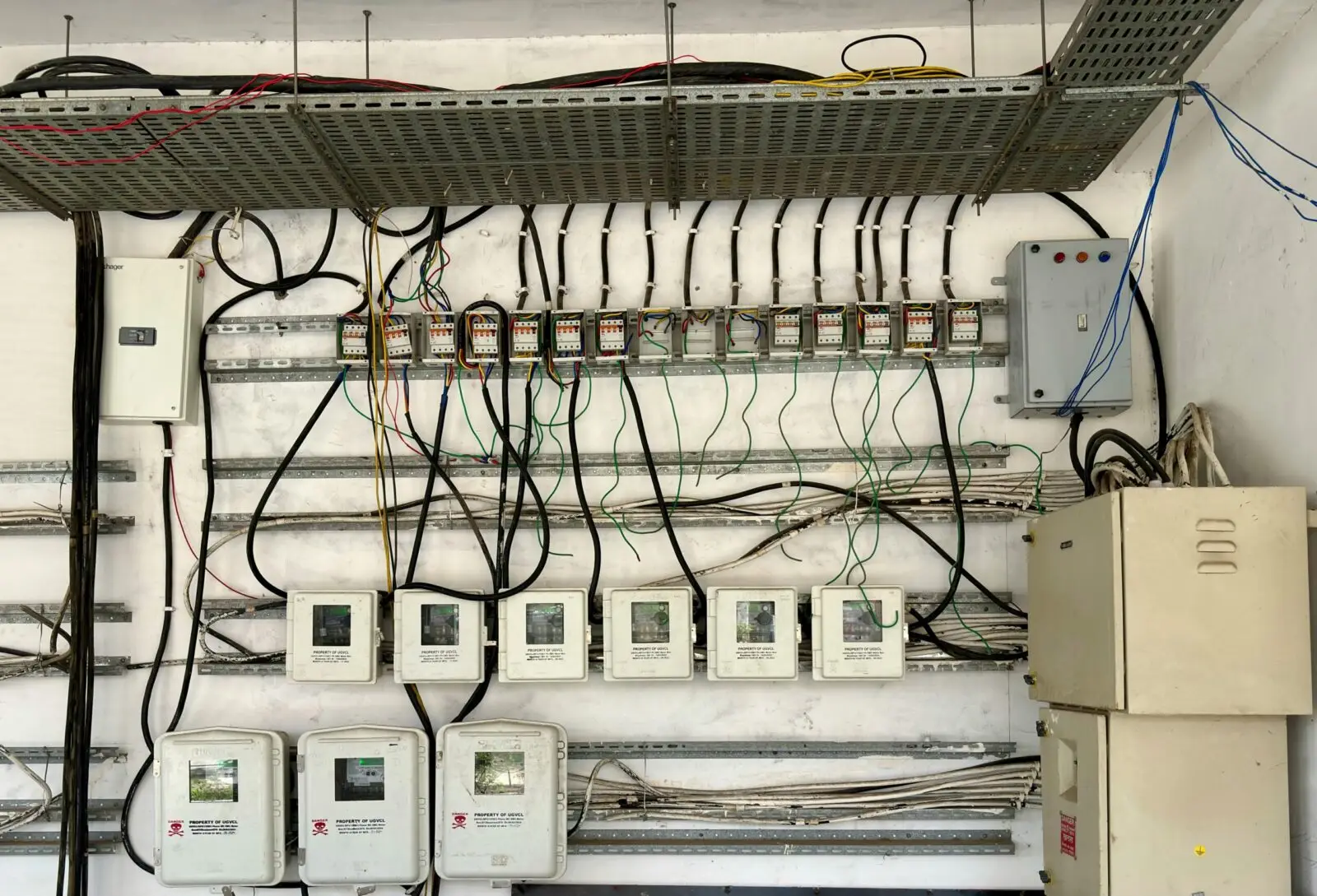

As an electrical technician, you face various situations daily. Some of these go unnoticed. Nevertheless, they can lead to potential issues down the line. Here are some faulty encounters you should be aware of:

- Incorrect Wiring: This can happen when wires are connected to the wrong terminals. Although it does not cause immediate problems, it can lead to malfunctioning equipment or even electrical fires.

- Overloaded Circuits: Failing to recognize when a circuit is overloaded can lead to overheating and tripped breakers. It’s essential to be mindful of the load each circuit is carrying.

- Loose Connections: Sometimes, connections are secure but are actually loose. These can result in voltage drops, flickering lights, or even equipment damage over time.

- Inadequate Grounding: If a system isn’t properly grounded, it seems functional initially. Nonetheless, it can create safety hazards. It also affects the performance of sensitive equipment.

- Using Incorrectly Rated Components: Installing components that aren’t rated for the specific application can cause failure. For instance, using a lower-rated fuse or breaker can lead to dangerous situations.

- Neglecting Continuity Checks: Not checking for continuity can lead to overlooking broken wires or faulty connections in a system. This can manifest as intermittent issues that are hard to trace.

- Ignoring Code Violations: Sometimes, technicians overlook code violations due to either ignorance or haste. This can lead to safety hazards and potential legal issues.

- Overlooked Maintenance: Failing to schedule regular maintenance can lead to unnoticed wear and tear on components, leading to unexpected failures.

- Misdiagnosing Faults: It’s common to misinterpret electrical symptoms. This mistake can lead to replacing the wrong components. It wastes time and resources.

- Environmental Factors: Underestimating the impact of environmental factors, like moisture or temperature fluctuations, can lead to unexpected equipment failures.

Be vigilant and regularly review your work. This can help mitigate these unnoticed faults. It ensures everything operates safely and efficiently.

using WordPress and

using WordPress and

No responses yet